Planeterraeum

04.14 – 12.14

Over the course of a 10-month period in 2014, a small group of students from the University of Waterloo designed and constructed an installation for Toronto’s annual all-night festival Nuit Blanche. The installation was an 8-meter geodesic dome, outfitted with video projects and sound. Traditionally, geodesic domes have been the architectural typology of planetariums. For this reason, they have become the de facto place to explore the unknown and experience a world outside of your own. In our installation, we sought to build a space for pedestrians to gather and experience the life of the city from an alternative perspective.

Portraying the unseen perspective of Toronto’s downtown, ‘Planetarium’ projected video feed from an over-head drone onto the multifaceted interior walls of the geodesic dome. By inverting the image seen over the downtown onto the ceiling of the dome, we allow the public to orient themselves in their city from 100 meters in the sky. This alternative perspective affords a glimpse into how the viewer relates to the complexity of the city below. The project was designed with the clear intent of easy transportation and quick assembly and disassembly.

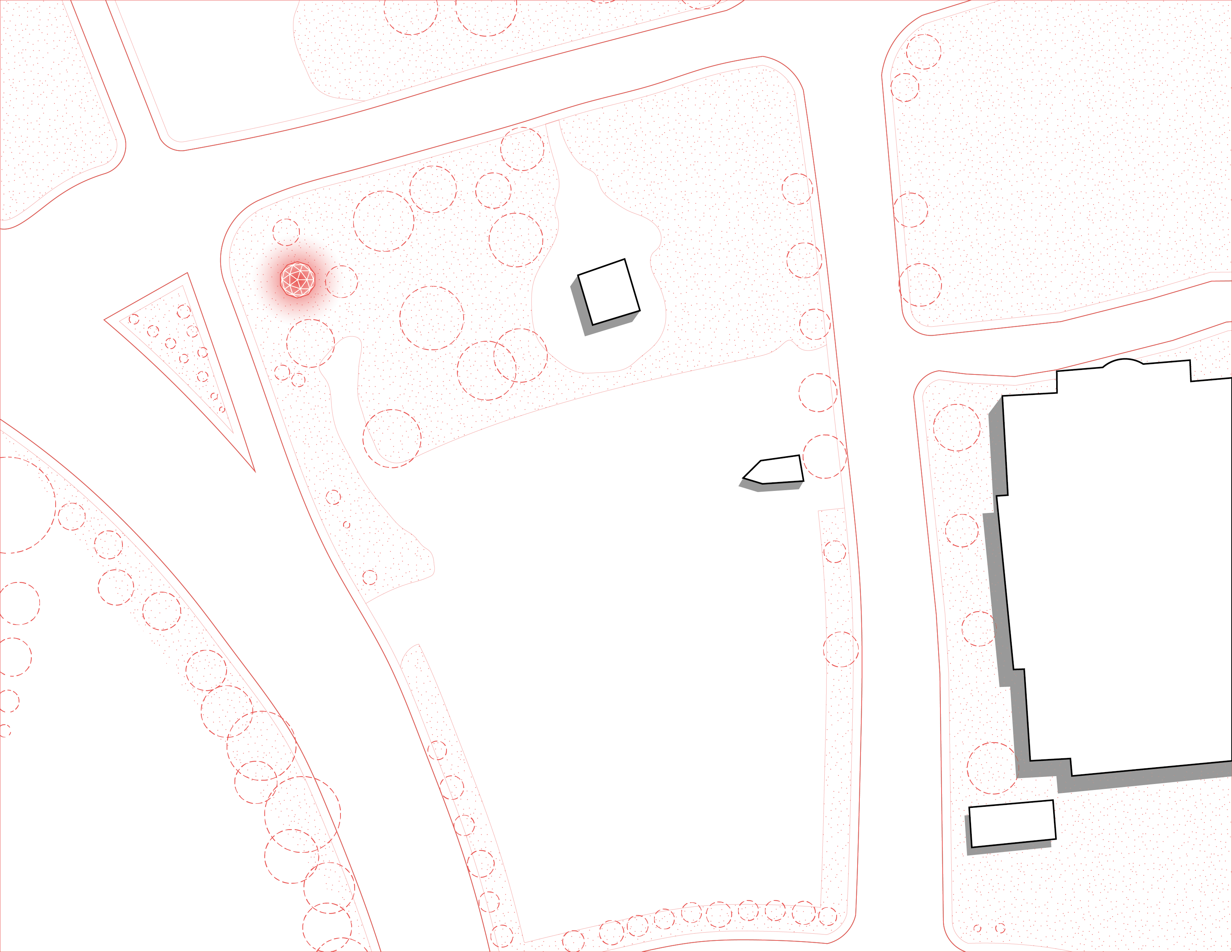

Site

Site Plan / Toronto Harborfront

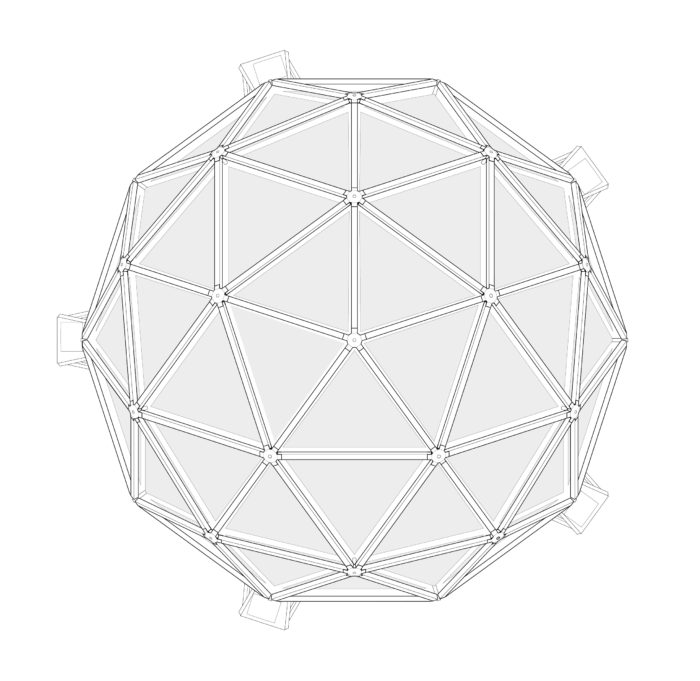

Plan

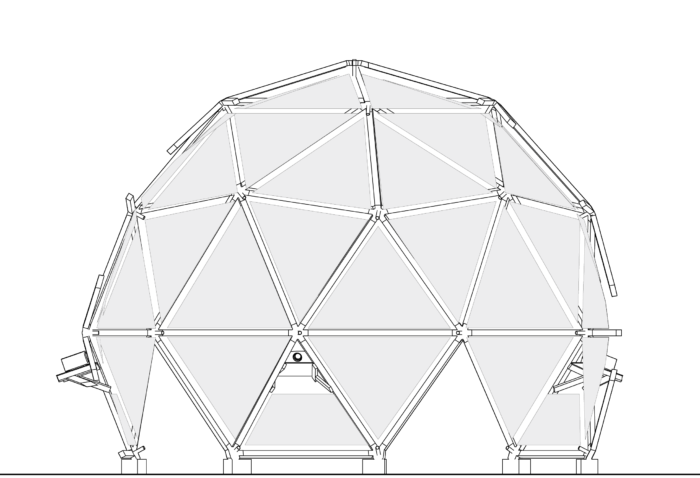

Section / Typical

Design Process

The Structure

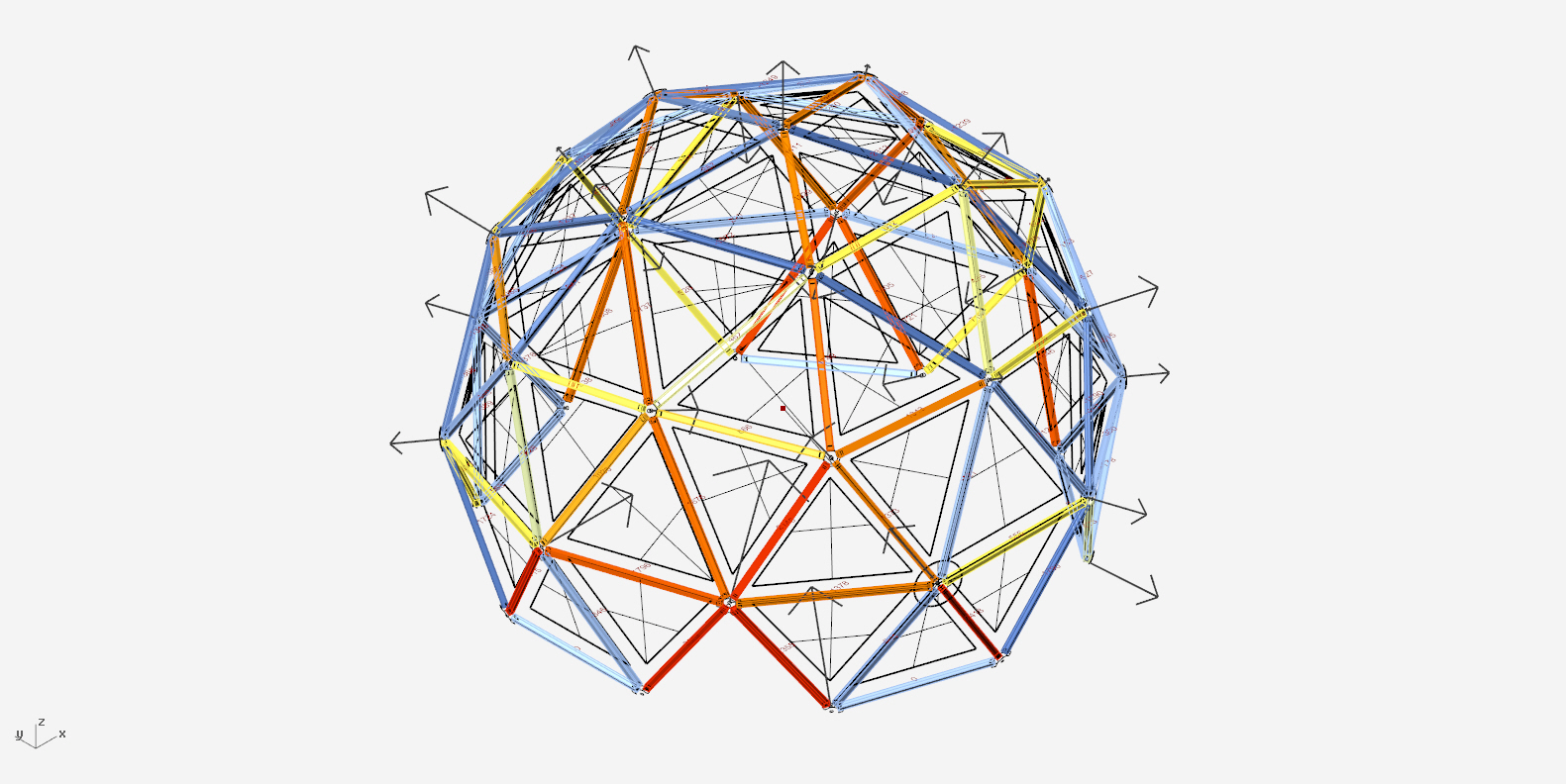

In order to build a geodesic dome, we first needed to have a comprehensive understanding of the structure we were building. Our initial tests allowed us to see how different levels of subdivision (i.e. number of faces) would affect the size of each face, the base of the dome, and total amount of material. By understanding how the amount of faces affects other aspects of the design, we were able to make informed decisions early in the design process.

Another design strategy was the group consensus to build 1:1 as early as possible. This method of constantly prototyping allowed us to develop a refined sense of scale, an understanding of material connections and the assembly of the structure.

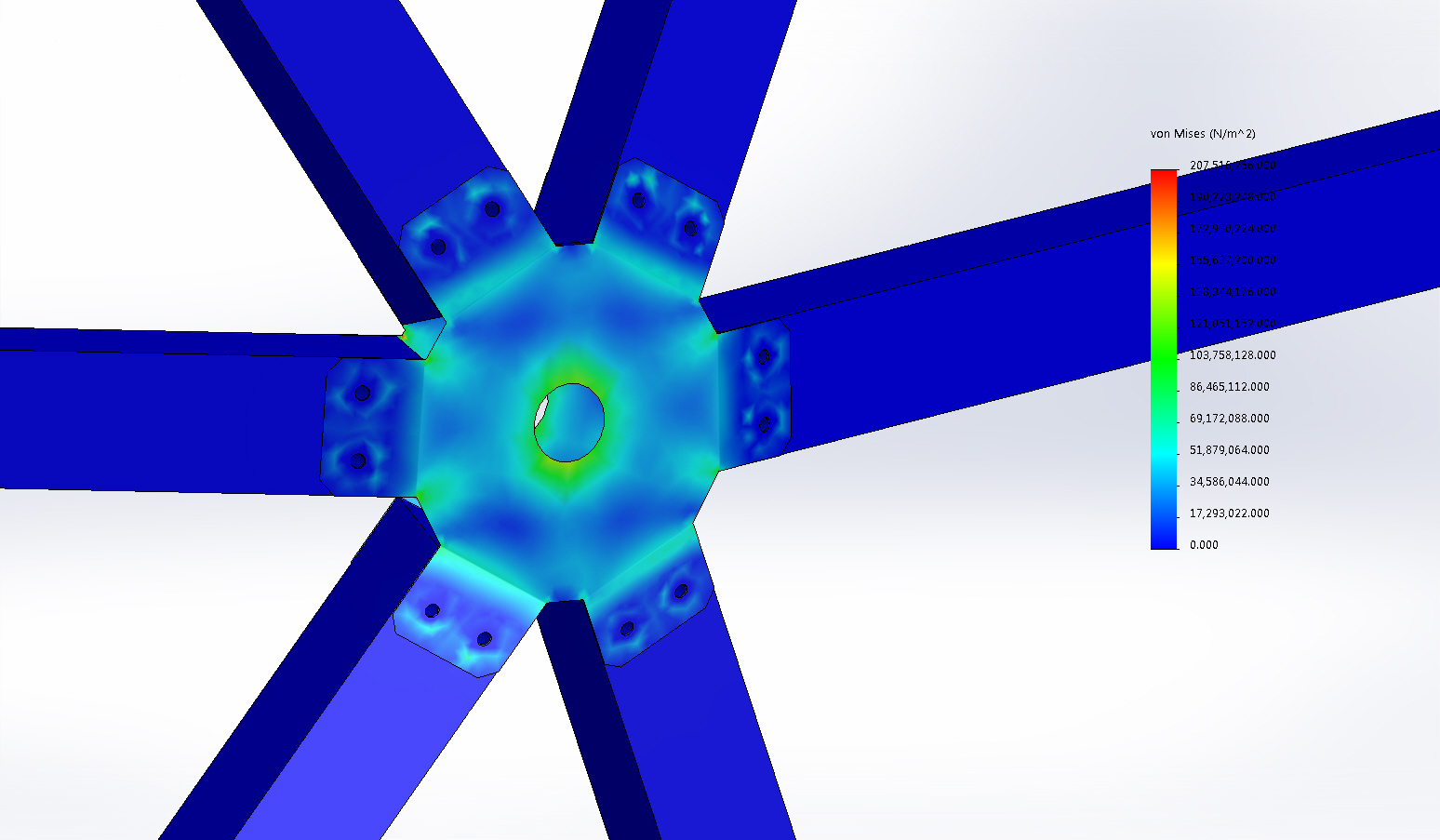

In approaching the structural questions of the project, we began by constructing a 3D model in conjunction with Grasshopper – a tool that would, in this case, allow us to monitor the stress on each member. By scaling the size of the dome, our Grasshopper plug-in would calculate loads, weights, size of members, and costs.

In order to account for the possible wind loads, the structure had to be sturdy enough not to up-lift or break. This was one reason we chose to use Laminated Strand Lumber (LSL), a material that, although more expensive than other lumber, was structurally appropriate and less likely to warp.

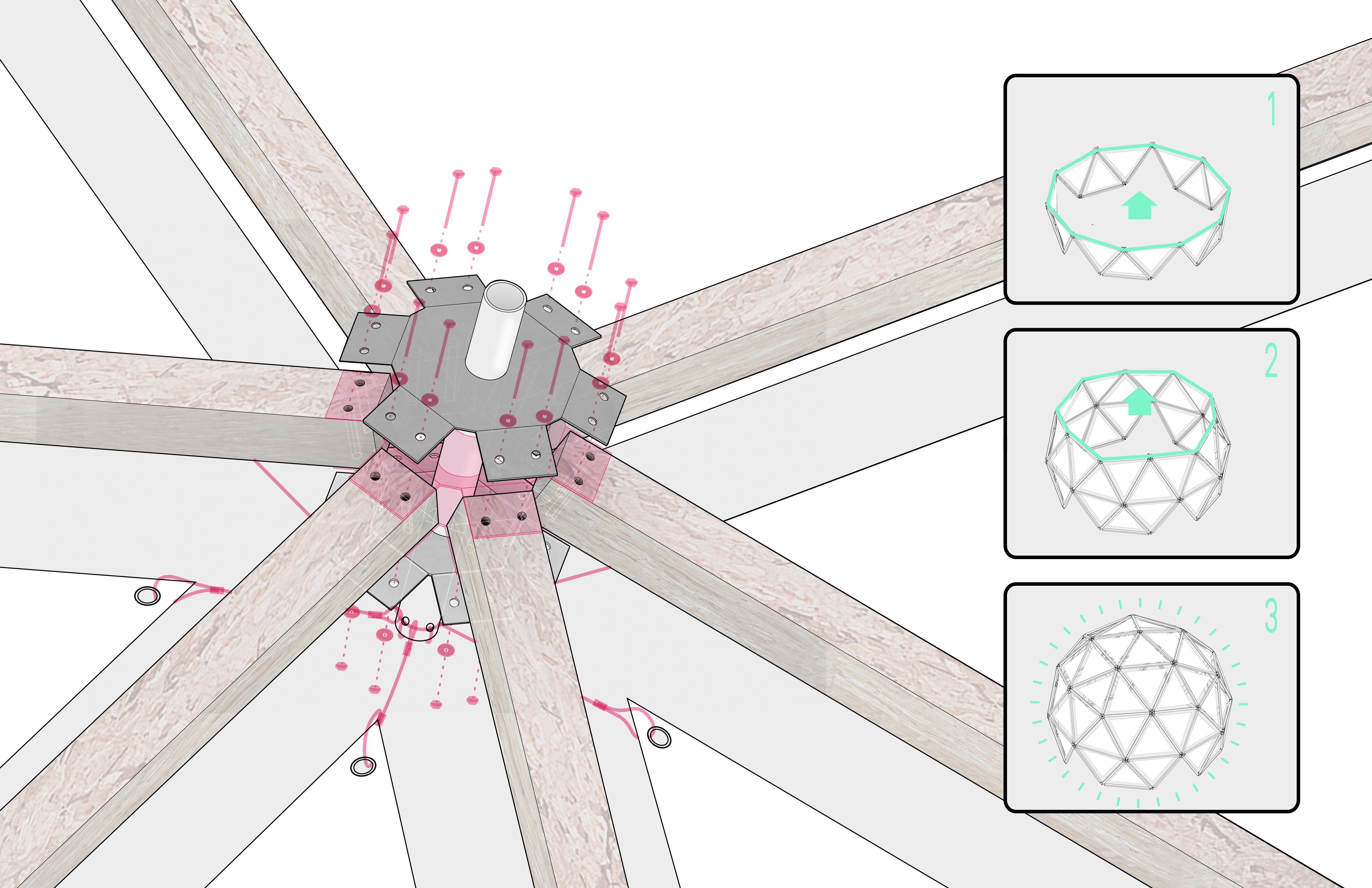

Given the weight of the LSL beams, it was imperative to use steel joints. Using a plasma cutter we were able to cut the joints with a necessary high-degree of precision. Additional concrete foundations were used in order to secure the final structure to the ground.

Like many other design/build projects, the size of the truck we would use was a constraint we considered from the beginning. Given the standard 8-foot height of a loading truck, we designed for the largest triangular preassembled piece (3 LSL members connected to their respective steel-joints) to stand at 7.95 feet.

Onsite, we assembled the remaining pieces that were not preassembled. This would require hundeds of screws, and building a temporary interior scaffolding structure to reach the top. Afterwards the sails were mounted onto the wooden structure and the projectors were fastened and covered with tarps.

Installation

Once we arrived on site, we had approximately 10 hour until sundown. Working in teams, we first placed down the foundation blocks, then aligned the pre-assembled pieces on top and secured them. Next, we built two scaffolding decks and rotated around the dome in teams, fastening and securing the members. Then we attached the triangular sails to the joints with bungee cords.

Once the structure was built, we began setting up the projectors on their mounts and prepping necessary components for possible rainfall. Finally, after the structure was built and the electronics were wired, we cleaned the site for nightfall and cued the music.